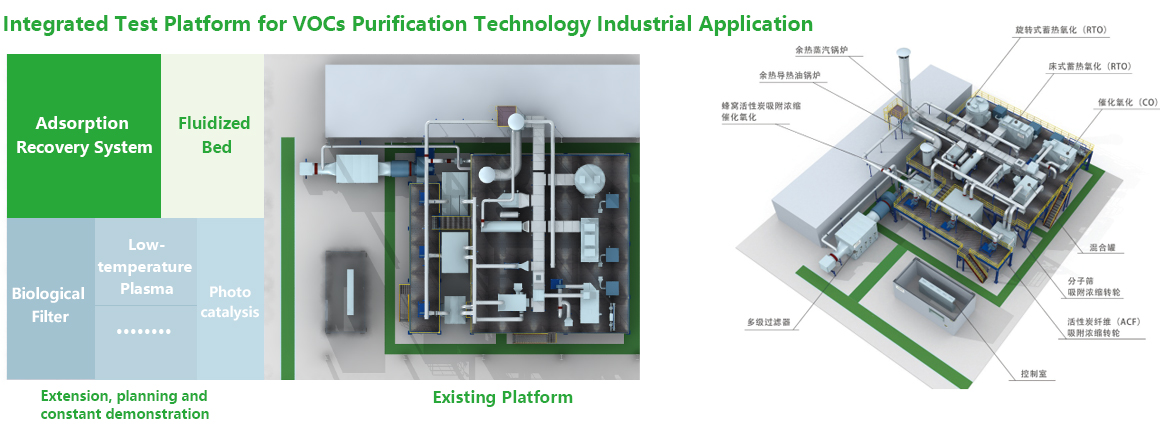

Qingdao Napotec Environmental Protection Technology Co., Ltd. (hereinafter referred to as Napotec), is a high-tech private enterprise integrating research and production. Our company, jointly with South China University of science and technology, has successfully established a National Engineering Laboratory in VOCs Pollution Control Technology and Equipment. The establishment of the laboratory is beneficial to establish the advanced, environmental protection technology R&D test facilities in industrial scale, build long-term industry-university-research integrated test platform for VOCs purification technology industrial application, enhance the technological and equipment level of VOCs treatment industry, and promote international cooperation and exchanges in engineering technology R&D applications.

As a founder of National Engineering Laboratory, our company will adhere to an open mind to demonstrate the domestic advanced VOCs technology and equipment via the platform, which other units in the industry may realize engineering project cooperation to popularize the advanced technology and promote the common development of VOCs treatment industry.

Process Development and Technical Optimization

Working Condition Simulation

Test Demonstration

Process Development and Technical Optimization

Working Condition Simulation

Test Demonstration

Technical Demonstration and Promotion by Environmental Protection Department

Process Selection, Demonstration and Optimization by customers

Technical Demonstration by Peer

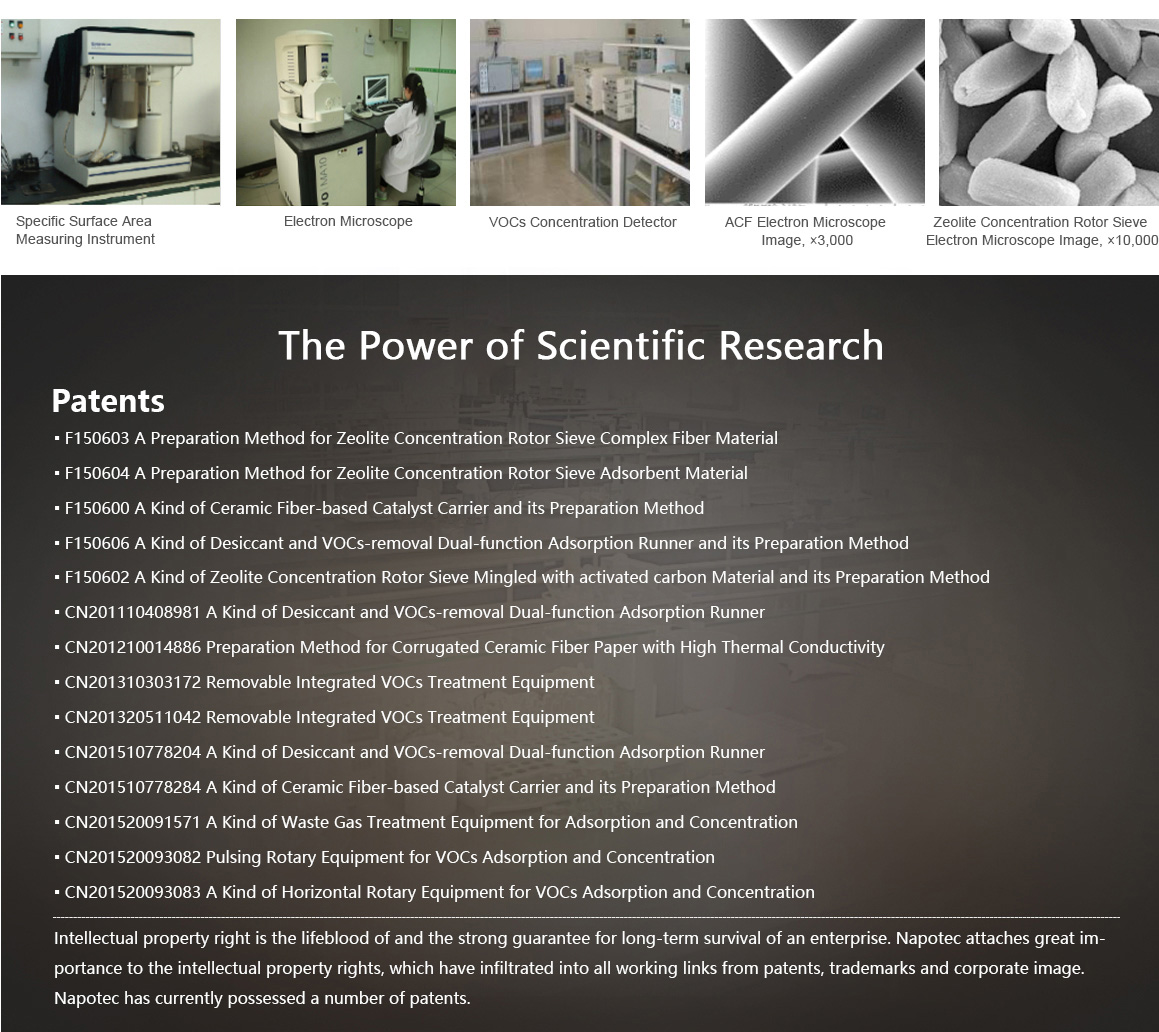

The company is equipped with independent professional R & D institutions. Covering an area of 2,500m2 and having a total value of laboratory equipment over RMB 10 million yuan, the laboratory is equipped with various modern facilities for basic research for VOCs treatment application and has the basic ability to undertake VOCs treatment technology research. The major facilities include: electron microscope, VOCs concentration detector and specific surface area measuring instrument, providing strong scientific support for the development of more VOCs treatment products.

Napotec R&D Department will perform multiple small-scale tests and pilot tests on the new environmental protection equipment and core materials prior to formal production, to explore the best solutions in line with actual production applications. At present, there are several sets of engineering pilot plants: small-scale test and pilot plant for absorbability evaluation, pilot plant for VOCs integrated treatment, providing an important conditional guarantee for the rapid conversion of laboratory research achievements.

We have 5S standardized management production workshops, clearly divided into different areas according to the type of work, including welding fabrication base, machining operation base, assembly display base and core material development base, and have achieved operation process standardization, product production flexibility, perfect equipment and tooling, safety culture standardization, product quality automation, on-site management visualization, encourage diversification, and real-time exception handling.

Our company's scientific research technology has reached the international advanced level in the manufacture of environmental protection equipment and the research and development of core materials in the VOCs treatment industry. Having taken the lead in the technology innovation investment which is well above the industry level, the company mainly focuses on the industry-university-research integration of the "Heart" of environmental protection equipment for the purpose of achieving the powerful combination of "First Kilometer" and "Last Kilometer" proposed by Premier Li Keqiang. Our company has established a cooperative relationship with various famous universities and institutes in China, such as University of Science and Technology of China, Institute of Coal Chemistry, Chinese Academy of Sciences, Ningbo Institute of Industrial Technology, CAS, Tianjin Polytechnic University, China University of Petroleum, North University of China, Shandong University of Science and Technology, to achieve continuous innovation of new VOCs treatment technologies.

Our company has achieved a mature application of VOCs treatment technology in the commonly used international VOCs treatment technologies, including biological, physical and chemical methods, and now is performing pilot test on biological filter bed to overcome all kinds of technical difficulties; at the same time, our company has achieved breakthroughs in various treatment technologies as high-temperature plasma, low-temperature plasma and fluidized bed technology and driven the rapid development of environmental protection industry through technology R&D.