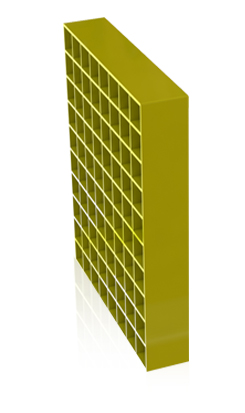

Low temperature SCR catalyst with monazite structure is a new type catalyst which is self-researched by Qingdao Napotec Environment Protection Technology Co., Ltd. with intellectual property rights. Adopting ceramic honeycomb with light weight, low heat capacity and high strength as carrier, SCR catalyst is coated with transition layer and high activity SCR catalyst coating in the surface. V-W-Ti is used as an active ingredient and a special coating process is used to attach the catalyst to the surface of the carrier.

Catalyst has excellent low temperature activity, anti-thermal shock and anti-poison performance with high specific surface area. Its excellent material performance can reduce the heating time of catalyst enormously which can reach the initiation temperature of catalyst quickly and make the SCR happen reaction. Under the condition of high concentration of NOx and airspeed, the removal efficiency of NOx keeps above 90%, and at the same time, it remains a relatively low amine escape rate. The outline dimension and pore density of catalyst is reasonably designed in accordance with application requirements and waste gas condition to ensure the utilization rate of catalyst.

Low initiation temperature NOx removal efficiency can keep above 90% under design condition

Low initiation temperature NOx removal efficiency is more than 90% under 170 to 180℃

Wide temperature window keep great denitration efficiency under 170 to 400℃

Good stability and long service life pecial catalyst prescription and manufacture process attribute to enhance the mechanical strength, stability and service life of catalyst。

Low investment and running cost: lower initiation temperature is supported by discharge temperature of low temperature exhaust gas, to avoid the huge running cost owing to the secondary heating of waste gas, realizing energy saving, emission reduction and surplus heat utilization

Flexible structure design, modular assemblyadjust the shape, outline dimension and pore density of catalyst flexibly in accordance with different requirements; modular assembly of catalyst unit reduces the manufacture intensity and cycle to realize the modular installation, commissioning and replacement.

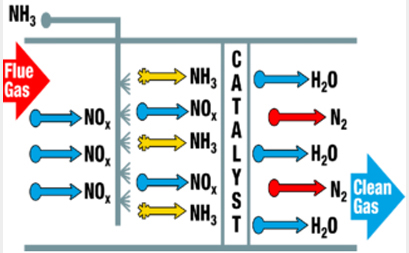

SCR catalyst is currently the most widely used denitration technology with the highest efficiency, which can be widely used in station boiler, industry boiler, waste incineration, industrial process and NOx emission control of motor vehicle exhaust, and the NOx removal efficiency is more than 90%, thus it is the most effective technology to control NOx emission of fixed source and moving source. Low temperature SCR catalyst, which means the quick SCR reaction under relatively low exhaust gas temperature (170℃) referring to reducing agents like hydrogen nitride or carbamide do selective catalytic reduction with NOx in the waste gas on the surface of catalyst, transforming the NOx in the waste gas into N2 or H2O which are non-toxic, and keeping high removal efficiency of NOx. The main reactions are as below:

(1)4NO+4NH3+O2→4N2+6H2O

(2)2NO2+4NH3+O2→3N2+6H2O

(3)NO+NO2+2NH3→2N2+3H2O